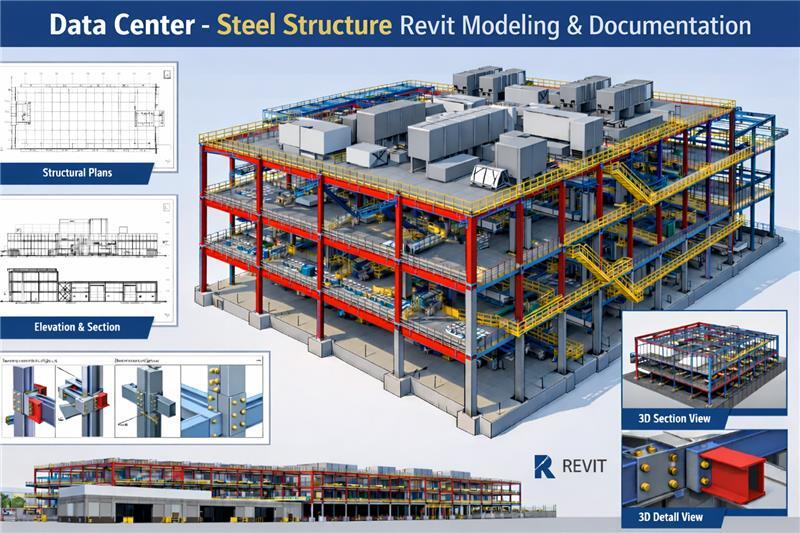

The client is a leading provider of innovative solutions for data center containment and commercial building insulation in the form of structural ceilings and raised access floorings. For over five decades, this Australian giant has leveraged advanced technology in delivering sustainable and high-performance projects.

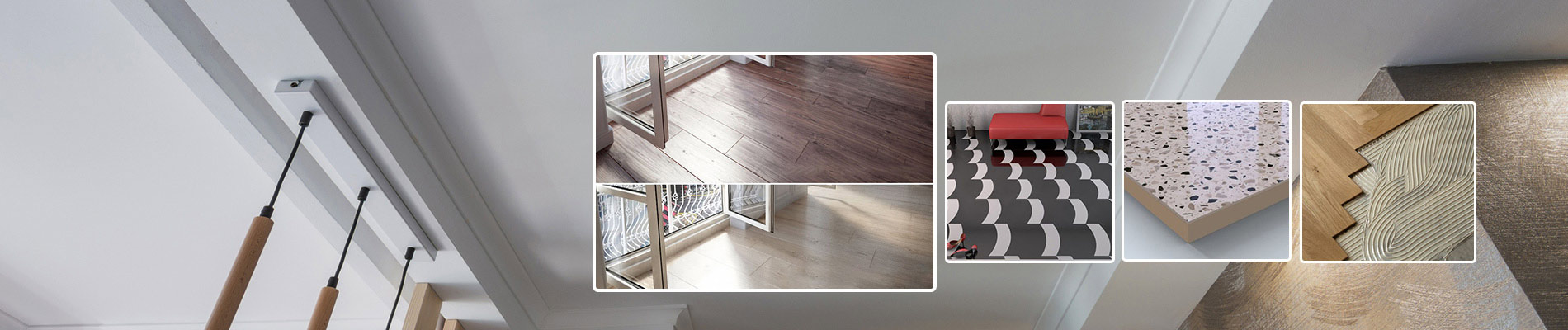

As a specialist in flexible, modern, and adaptive raised access flooring, our client is also a manufacturer of customized building objects loaded with powerful features for urban/corporate living. With a scientifically designed vast product line, the client is a renowned name in the niche segment of the industry and undertakes projects specific to – airports, data centers, casinos, corporate building, etc.

Requirement - Coordinated Revit model with raised access flooring systems

Learning about the building product modeling capabilities of eLogicTech, the client approached for a coordinated Revit modeling project. The requirement was to generate Revit models of the raised access flooring systems with a total count of the floor panels and pedestals. For the 13-floor commercial building, the client had provided the Revit template and the hand sketches as input documents. As part of the project scope, the following output documents were required by the client:

- Coordinated Revit Model (RVT)

- Floor plans (RVT, PDF & CAD)

- Schedules (RVT, PDF)

Modeling different panel types and tight delivery timeline among the challenges

The major challenge that this coordinated Revit modeling project brought in was to understand the panel types and develop the 3D models based on the specifications. eLogicTech’s Revit family creation team segmented the building products and understood the requirement from the sketches. It was then easy to develop the models following the Revit template.

Another usual challenge was the tight deadline that the team handled by assigning the most experienced Revit specialist and proactive communication with the client.

Building product modeling process followed for the project by eLogicTech

Our detailed Revit model of the raised access flooring would be helpful for the client to fit in sub-floor MEP systems with sufficient air space and aesthetically pleasing patterns on top. The process followed to deliver the floor plans, and the coordinated Revit model was as follows:

Receiving the specifications and flooring templates in Revit, our team did the initial effort estimation.

The effort estimation was sent to the client for approval.

After the client’s approval, one experienced resource was assigned to this building product modeling project considering the defined deadlines.

The floor plans were re-visualized in AutoCAD and imported to Revit. The coordinated Revit models were developed based on the defined specifications.

After a two-level QC, the progressed Revit models were shared with the client on a daily basis.

All the feedbacks and mark-ups received from the client were incorporated. A version history was maintained with remarks.

The final floor plan drawings and the Revit model were quality checked, adhering to the specified building standards. All the final deliverables were shared with the client within the agreed timeline.

Takeaways - In-time deliveries meeting all the requirements and a satisfying client

As the client has a strict constraint of project delivery time, eLogicTech promised and delivered the entire project well within the agreed timeline. Moreover, the multi-level QC process, alignment of the building objects to the standard practices specified by the client we all met. The client was satisfied with our team on many fronts, including our proactive communications and assignment of a dedicated project manager to deal with the timeline rush.

Need Help?

Don't hesitate to contact us for more information about company or service

.jpg)

.jpg)